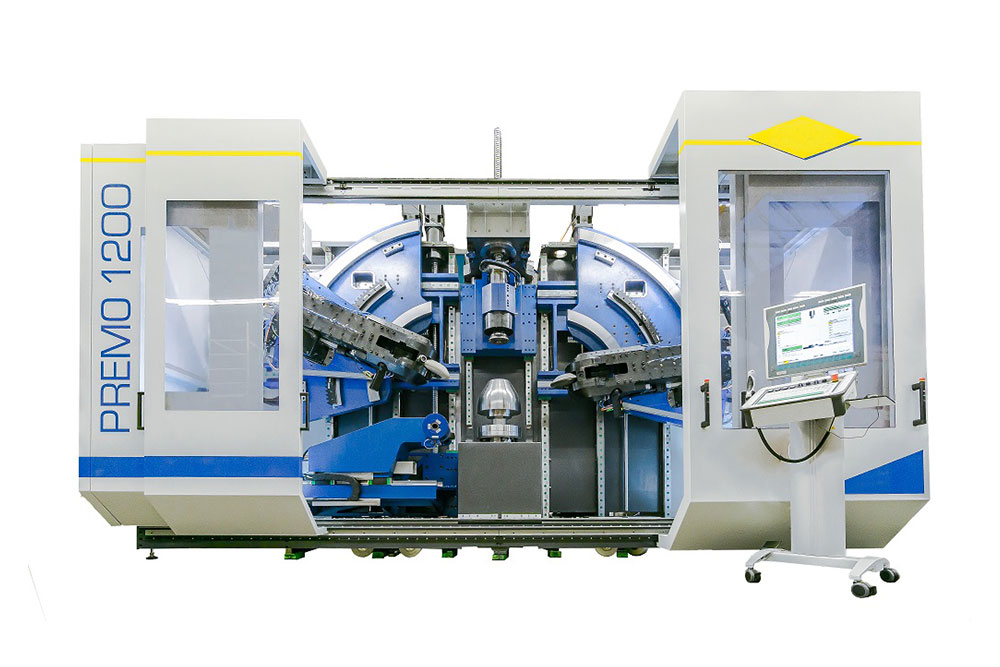

Our drive technology is used in a CNC-controlled, innovative spinning machine. This enables chipless forming even with large quantities and diameters up to 1,200 mm. The servo axis constructed from our components takes over the drive and guide functions for the manufacture of rotationally symmetrical products such as satellite dishes or tank caps.

A thin sheet metal disc (blank) is rotated on a lathe and pressed successively from the center into a shape using a tool (pressure steel, roller). The drive for the up to 13 axes of the CNC-controlled forming press is provided by heavy-duty ball screw drives supplied by us. These are optimally guided by our heavy-duty roller guides from the RG series. The torque required to move the quill is provided by torque motors from the TM-5 series, which are specially designed for machine tools.

Metal spinning with high efficiency and precision – our drive technology makes pressure.

Requirements:

- Robust and resistant

- High precision and short cycle times

- Short delivery times

HIWIN components:

Areas of application:

- Forming technology

- Machine tools

- Automation